How To Reduce Emulsion Loss and Avoid Fines

- Feb 21, 2022

Imagine following all state and local grease management regulations and STILL receiving a non-compliance fine because grease in your city's wastewater system was traced back to your kitchen. Your grease trap is working as it should. Your kitchen practices are on point. What is going on? The answer is ...

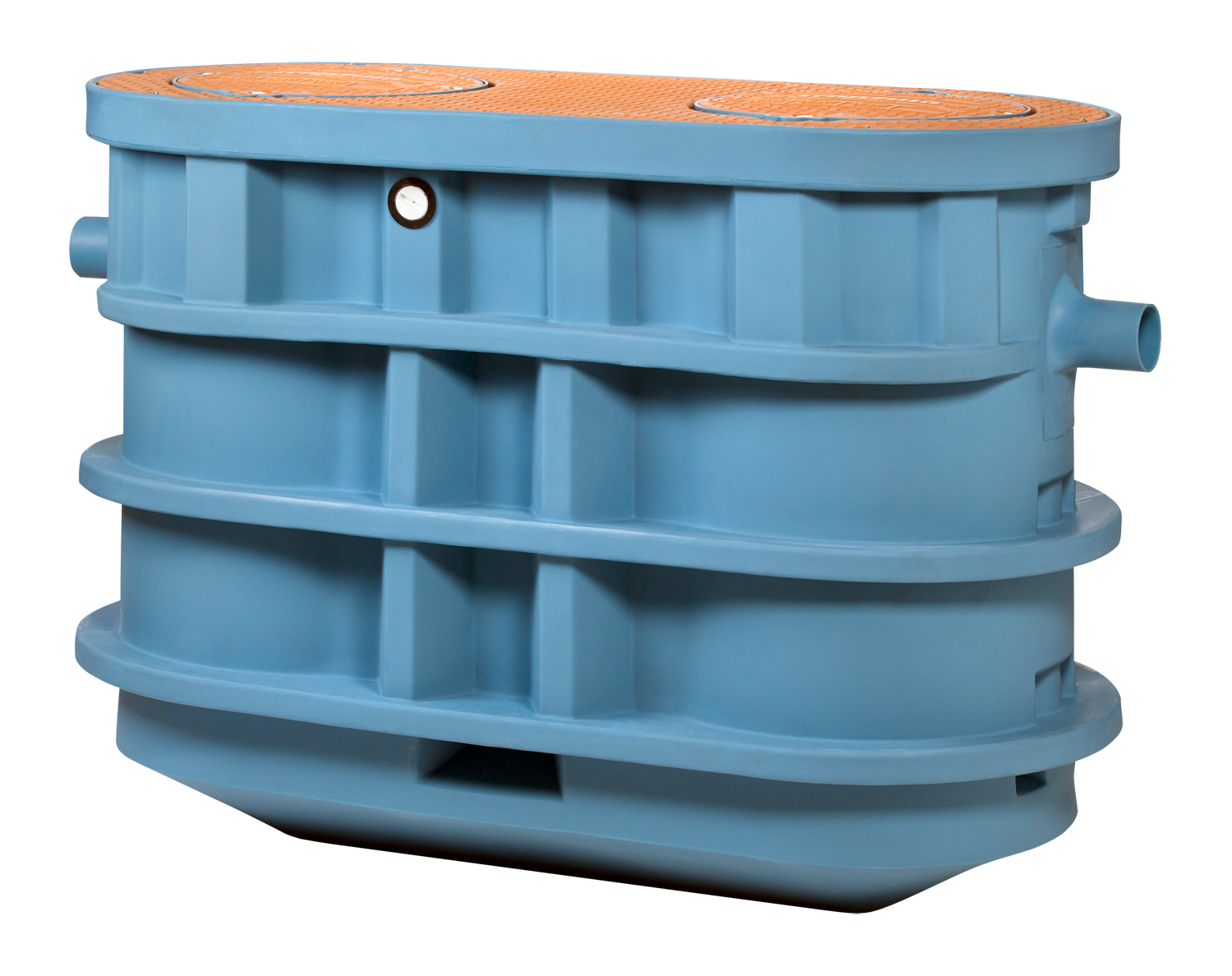

What is your plan when a city official, contractor, or engineer says a 1,000-gallon grease interceptor must be installed in your drive-through, parking lot, or another area where vehicles will be driving over it every day?

What is your plan when a city official, contractor, or engineer says a 1,000-gallon grease interceptor must be installed in your drive-through, parking lot, or another area where vehicles will be driving over it every day?  Commercial kitchen operators already know the benefits of using grease interceptors to capture used oil and grease -- cleaner sewage systems, reduced costs for wastewater treatment plants and fewer fines from municipalities.

Commercial kitchen operators already know the benefits of using grease interceptors to capture used oil and grease -- cleaner sewage systems, reduced costs for wastewater treatment plants and fewer fines from municipalities.

It happens every year during the holidays: Home cooks rev up their ovens and deep fryers and in go millions of turkeys in preparation for Thanksgiving day feasts.

It happens every year during the holidays: Home cooks rev up their ovens and deep fryers and in go millions of turkeys in preparation for Thanksgiving day feasts. Fats, oils and grease (FOG) in wastewater are one of the biggest challenges facing wastewater systems around the world. Grease, sometimes along with solids, can build up into a solid mass that can narrow or even block wastewater pipes. When that happens, sewers overflow, pipes break, and local authorities are forced to clean up the mess and make repairs.

Fats, oils and grease (FOG) in wastewater are one of the biggest challenges facing wastewater systems around the world. Grease, sometimes along with solids, can build up into a solid mass that can narrow or even block wastewater pipes. When that happens, sewers overflow, pipes break, and local authorities are forced to clean up the mess and make repairs. A commercial kitchen wouldn’t repeatedly send 200 gallons of burning water and 20 pounds of hot lard through its grease interceptor even on the busiest night. And a blizzard would make it even less likely.

A commercial kitchen wouldn’t repeatedly send 200 gallons of burning water and 20 pounds of hot lard through its grease interceptor even on the busiest night. And a blizzard would make it even less likely.  To understand the new TZ-1826 Trapzilla Grease Interceptor, consider two numbers: 1,826 and 11,000.

To understand the new TZ-1826 Trapzilla Grease Interceptor, consider two numbers: 1,826 and 11,000.  Business managers might feel as if their lives revolve around quarters … quarters of the year, that is. From taxes to financial reports and marketing initiatives, managers have a laundry list of tasks to accomplish four times a year. Food service establishment operators have yet one more responsibility to tackle at least once a quarter — the pumping of the grease trap.

Business managers might feel as if their lives revolve around quarters … quarters of the year, that is. From taxes to financial reports and marketing initiatives, managers have a laundry list of tasks to accomplish four times a year. Food service establishment operators have yet one more responsibility to tackle at least once a quarter — the pumping of the grease trap.