Look what happened when we combined 19,200 gallons of water and 1,920 pounds of lard

- Sep 8, 2015

A commercial kitchen wouldn’t repeatedly send 200 gallons of burning water and 20 pounds of hot lard through its grease interceptor even on the busiest night. And a blizzard would make it even less likely.

A commercial kitchen wouldn’t repeatedly send 200 gallons of burning water and 20 pounds of hot lard through its grease interceptor even on the busiest night. And a blizzard would make it even less likely.

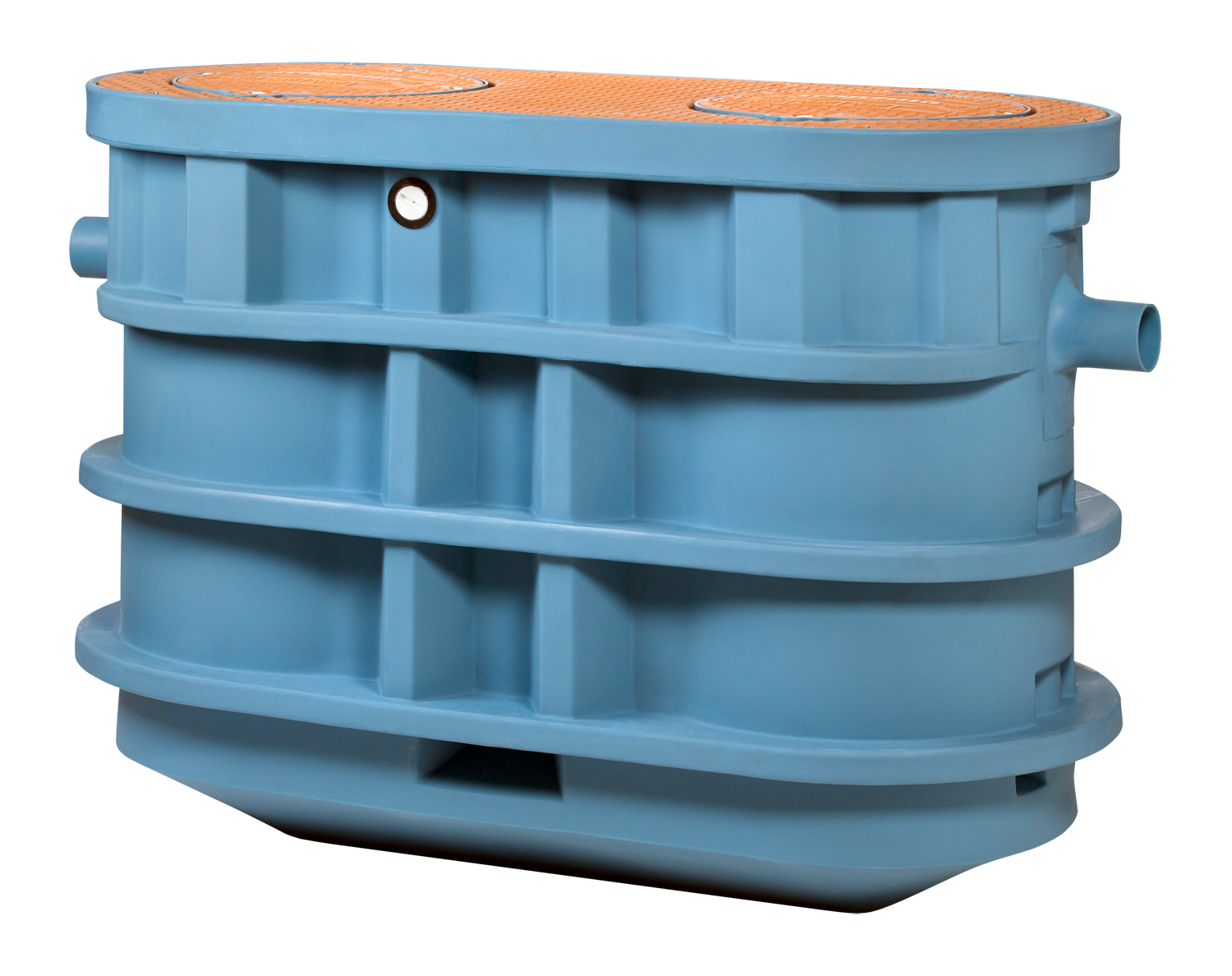

But this past February, that’s what we subjected our newest grease interceptor, the Trapzilla TZ-1826, to — during a storm.

The TZ-1826 is the third-generation Trapzilla, with a tank design optimized to retain more grease in as small a footprint as possible. We tested the TZ-1826 to the ASME standard to determine its efficiency and capacity.

We didn’t expect what happened next.

To understand the new TZ-1826 Trapzilla Grease Interceptor, consider two numbers: 1,826 and 11,000.

To understand the new TZ-1826 Trapzilla Grease Interceptor, consider two numbers: 1,826 and 11,000.  For the past few decades, scientists have experimented with using all kinds of waste, from animal to human, to produce methane gas via anaerobic digestion.

For the past few decades, scientists have experimented with using all kinds of waste, from animal to human, to produce methane gas via anaerobic digestion. For the past couple of decades, yellow grease, or used fryer oil, has been the go-to source for biodiesel production. Each gallon of yellow grease produces almost the same volume of biodiesel.

For the past couple of decades, yellow grease, or used fryer oil, has been the go-to source for biodiesel production. Each gallon of yellow grease produces almost the same volume of biodiesel.  Business managers might feel as if their lives revolve around quarters … quarters of the year, that is. From taxes to financial reports and marketing initiatives, managers have a laundry list of tasks to accomplish four times a year. Food service establishment operators have yet one more responsibility to tackle at least once a quarter — the pumping of the grease trap.

Business managers might feel as if their lives revolve around quarters … quarters of the year, that is. From taxes to financial reports and marketing initiatives, managers have a laundry list of tasks to accomplish four times a year. Food service establishment operators have yet one more responsibility to tackle at least once a quarter — the pumping of the grease trap. Like many wastewater treatment facilities, the

Like many wastewater treatment facilities, the  The Asheboro Wastewater Treatment Plant was built in 1962, during a different era. The Cuban Missile Crisis was right around the corner and America had just launched a space race to put the first man on the moon.

The Asheboro Wastewater Treatment Plant was built in 1962, during a different era. The Cuban Missile Crisis was right around the corner and America had just launched a space race to put the first man on the moon. One size fits all might be an appropriate term for a rain poncho. Or a baseball hat fitted with an elastic band. Perhaps even a baggy pair of sweatpants with a drawstring. But, the term has no place in the world of grease pretreatment.

One size fits all might be an appropriate term for a rain poncho. Or a baseball hat fitted with an elastic band. Perhaps even a baggy pair of sweatpants with a drawstring. But, the term has no place in the world of grease pretreatment.  Organic and “natural” products and methods enjoy a glowing reputation in the marketplace. They’re able to command higher prices and for many people are a preferred choice when there is a choice.

Organic and “natural” products and methods enjoy a glowing reputation in the marketplace. They’re able to command higher prices and for many people are a preferred choice when there is a choice. In 1969, the Cuyahoga River in Ohio caught fire.

In 1969, the Cuyahoga River in Ohio caught fire.